How To Add Color To An Epoxy Floor

Make every step you take colorful and bright.

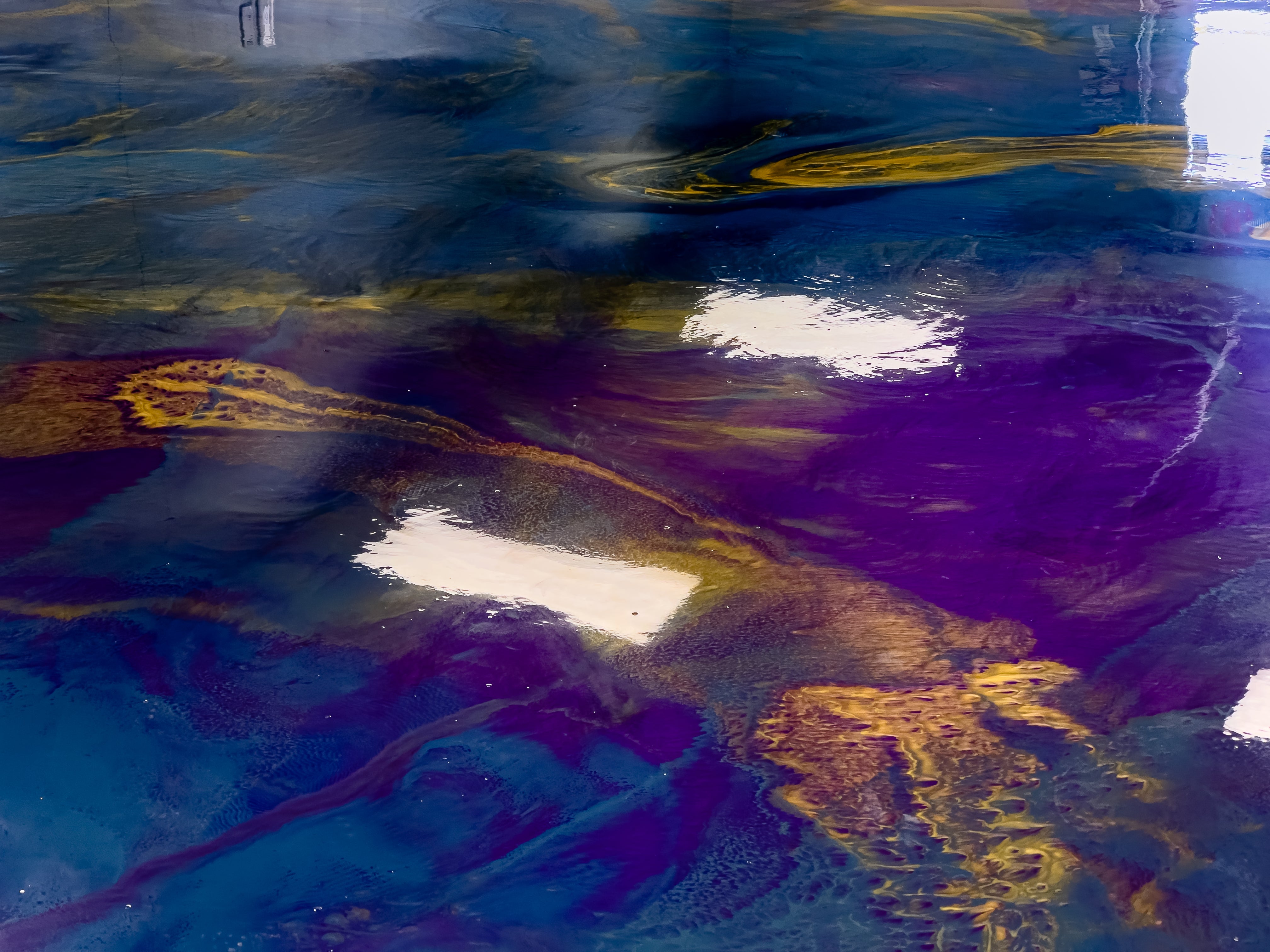

Epoxy has been growing in popularity as a flooring alternative for years, and its easy to see why. Between its long-lasting strength, and that clear coat finish that's become iconic, epoxy is a great investment for any floor. With the help of pigments designed to be used with epoxy, you can turn that great investment into something truly unique to you.

If you have any kind of artistic or creative vision for your space, pigments will help you achieve it. From subtle solid color epoxies, even to the most bold metallic or glitter floors!

Guide to Coloring Epoxy Floors

For any contractor who's installed epoxy, adding pigmentation to your process should be relatively simple. With a little experimentation and care, you'll be able to deliver beautifully colored epoxy floors to any client! Here's a step by step guide on adding pigment to your epoxy installation process:

1. Preparing for Installation

Building the foundation for your installation with care and attention is a direct investment in the quality of your finished floor. From ensuring the level of your concrete & its condition of its surface, to working with the right ratios of solutions, these are all essential epoxy skills.

It's equally as important to make sure you're using the highest quality products you can, such as the EpoxyETC or RockHard lines of epoxy resin, so you can trust that the floor will be solid, stable and sleek.

First in terms of surface preparation is the inspection and care for the concrete itself. Whether it's uneven, or its too rough (or even too smooth), you don't want your epoxy floor to be doomed from the start. Inspect its concrete surface profile, and grind out any imperfections you need to. Our article on understanding concrete surface profiles should help you get all the information you need to start on the right foot.

After you've ensured the integrity of the concrete, you'll need to mix the solutions. Each epoxy resin kit should come with instructions from the manufacturer. Generally, though, you'll be mixing two parts of your solution A (resin), with one part solution B (hardener). If you're careless with the ratio, or with the mixing process itself, you can render your epoxy completely unusable. Test in smaller batches if the mixing process is new to you!

2. Adding the Pigments to Your Mixed Epoxy Solution

While you're mixing your epoxy solution in the correct ratios, add in the pigment of your choice until you get your desired color! The manufacturer may let you know how much to add, but you truly can experiment as much as you want. Like the mixing process itself, it may be helpful to start in smaller batches so you can get a handle of the ratios you'll need to get your color just right.

If your, or your clients', creative vision involves a multiple colors, you may have to make smaller batches, and work more carefully. It's important to remember that epoxy left to sit out will continue its heating and hardening process, so be intentional!

What Should I Use To Color Epoxy?

There's a myriad of different methods for coloring epoxy. You don't need to get into the differences between mica-particles and iron oxide pigments. For most installations, simply choose a color you like from a distributor whose pigments are specifically designed for epoxy.

We have a few brands we know and trust on the market when it comes to epoxy pigments. HP Spartacote's solid colid colors are bright and beautiful, and designed specifically for their high-quality resin. On our EpoxyETC online store, you can choose from a variety of color charts for pigments designed to be used in your epoxy floor installations! Choose between a palette of solid color pigments or metallic epoxy pigments, and more!

Experiment, express your creative and deliver the floors your clients deserve with beautiful colors and a sleek finish!

3. Installing the Epoxy Floor

After everything is prepared for the installation, all that's left is to actually install the epoxy floor! Even with all the preparation in the world, if you're careless with this step, it could all be in vain.

When you use proper floor squeegees & metal tined spiked rollers, you're that much closer to success. You can increase your chances even more by investing in spiked shoes designed to be used during an epoxy installation! Apply the resin solution mix with long, even and careful strokes. Be sure to evenly distribute the solution across the entire floor.

This is where you can really start to express your vision. From the colors, to any streaks or veins, it's all there for you to customize! You can even go further and add in silica sand or vinyl flake broadcasts. Start with a primer coat to build your foundation, then either a finishing topcoat or a layered system with your broadcast of choice.

4. Epoxy Curing & Drying

At this point, your installation is almost complete, but the work isn't done yet. While each layer of epoxy you lay down needs to cure & dry on its own, the last cure & dry is the most important. Our article on epoxy curing & drying times can help you understand what this will mean for your installation schedule.

Patience during this stage of the installation is critical. If you disturb your epoxy solution before it has the chance to fully set in, all that hard work will be cancelled out. Make sure to let your clients, and your installers, know everything they need to about when the epoxy floor can be used fully. If you can do that, you'll be left with a beautifully sleek, brightly colored new epoxy floor!

And that's everything! With the help of this guide, and your own effort and skills, you can start delivering colorful new floors to your clients today!

Learn to Color Epoxy From Professionals

You don't need to be trained in art to create colorful epoxy floors for your clients, but training hands-on with professionals can massively improve your epoxy installation quality. With our Epoxy Classes program, you can learn from experienced installers everything you need to know, from start to finish, about epoxy. Our 5-day course will have you working hands-on to combine colors, broadcast flakes and more! Here's some of what we cover:

- How to mix pigments in epoxy to create your desired color

- Preparing your concrete surface to have epoxy installed on it

- How to grind concrete & apply self-leveling concrete

Help expand your flooring skills by signing up today!

Conclusion

Learning how to color an epoxy floor is an essential contracting skill for any floor installer. Not only will it help you achieve more beautiful floors, but it will help you satisfy your clients' creative vision for their floors! Experiment, get creative and start installing vibrant epoxy floors today!

Contractors with any questions about choosing a color, or installing epoxy in general, should call our technicians at (954) 287-3797. We also have our EpoxyETC online store that will deliver any resource you might need for your epoxy installation, at reasonable rates!