Epoxy is one of the most popular materials in the DIY home renovation toolkit right now. For home renovators and contractors alike, epoxy & resinous coatings generally are growing in trust and popularity each year - especially for flooring. For garage flooring or any other flooring project where you want to seamlessly blend strength and beauty, vinyl flake is the gold standard. Entrepreneuring contractor or DIY home renovator, epoxy resin has proven time and time again its ease of use and reliability.

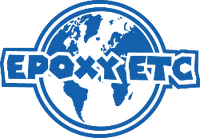

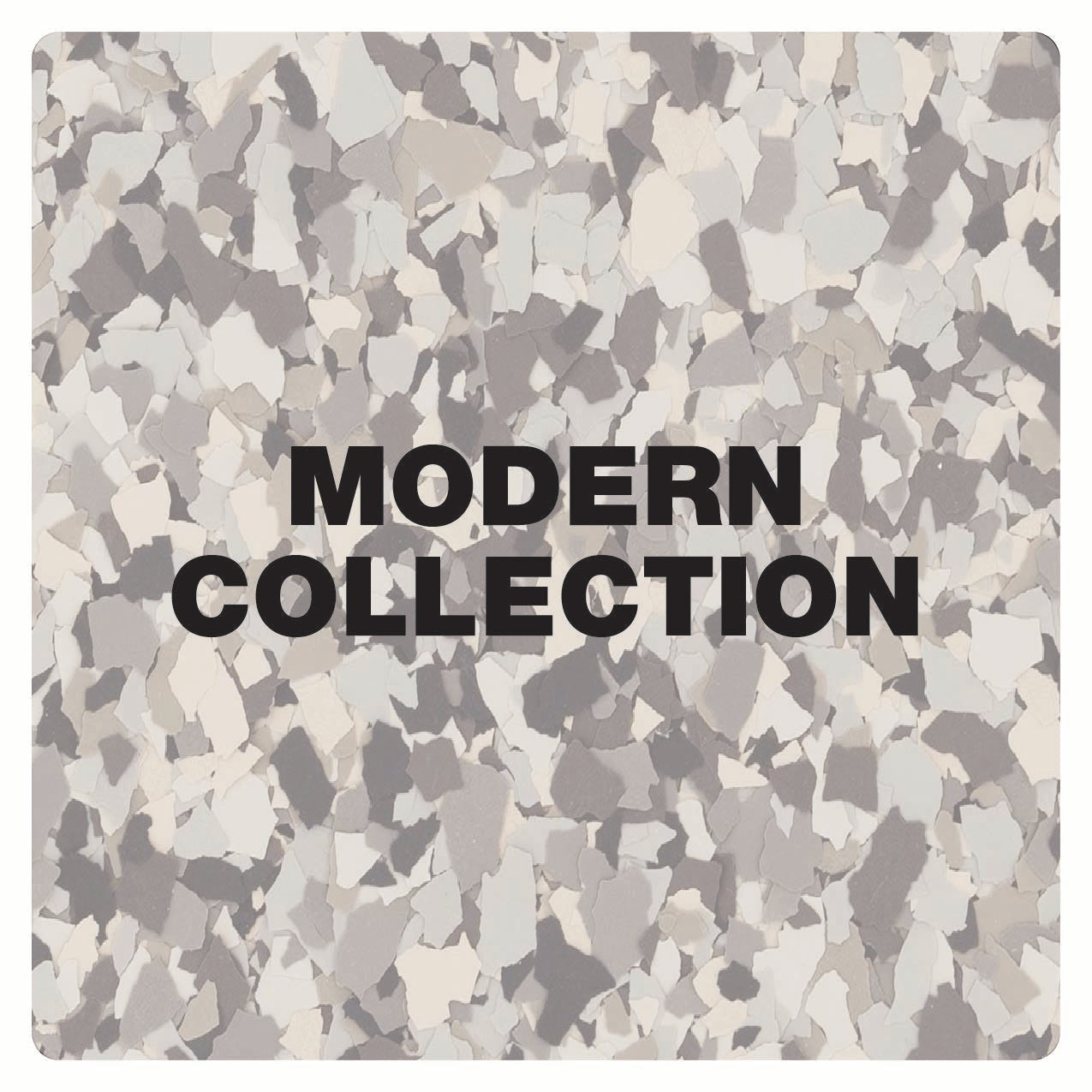

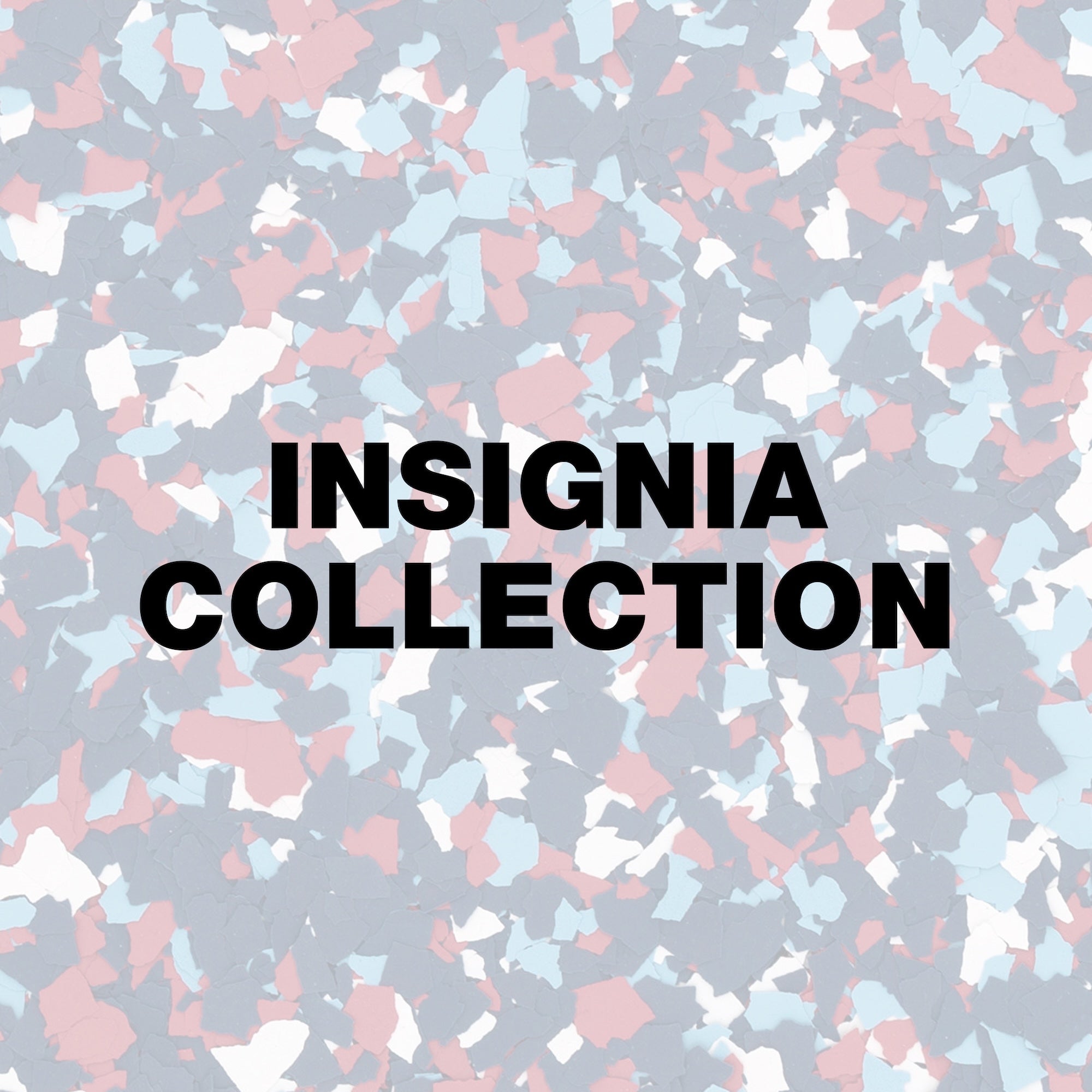

With our epoxy floor chip collection, you'll be able to access the full potential of that epoxy resin. EpoxyETC's vinyl flake collection is your best resource for finding high-quality, beautiful flake chips to install with your DIY epoxy resin floor. Each epoxy vinyl chip blend is built to fit and withstand garages, warehouses, commercial areas, residential areas, and more.