Cracked Concrete Crisis? Repair Like a Pro & Save Your Epoxy Floors (2025)

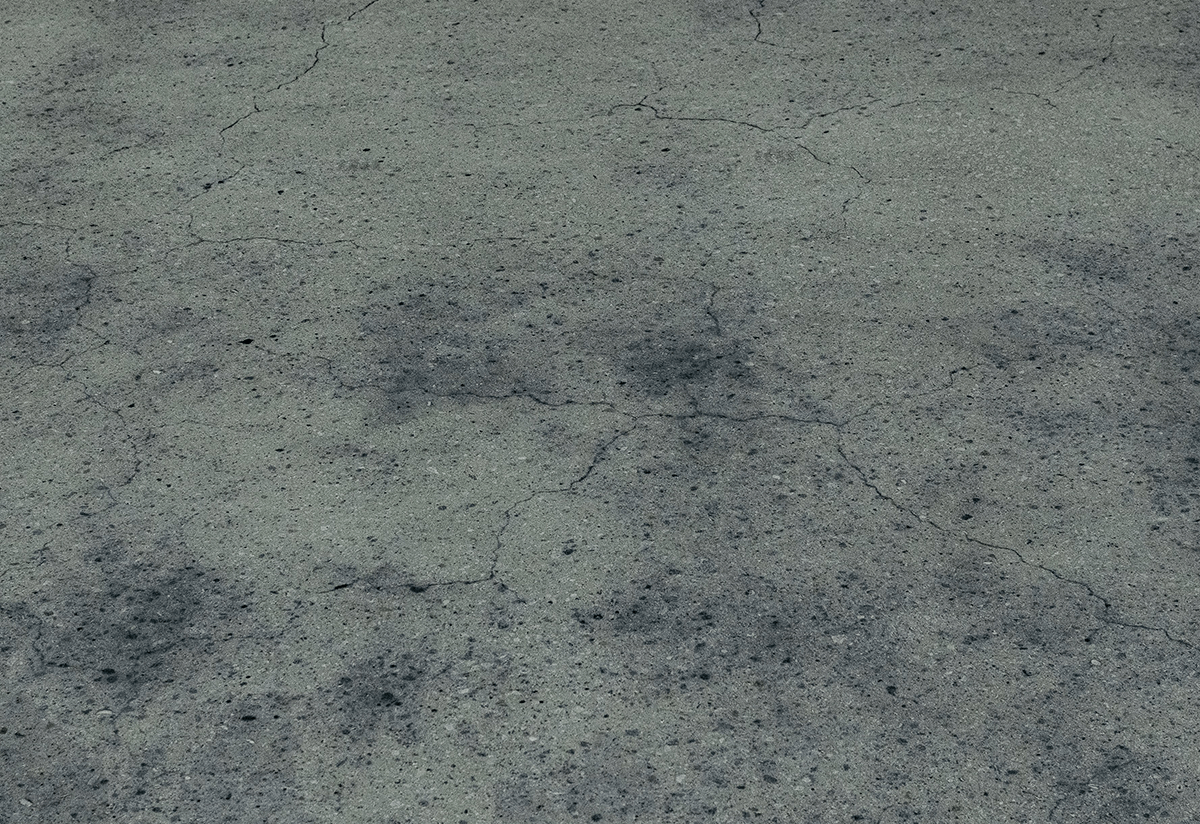

You just finished a flawless epoxy floor. The client is thrilled—until hairline cracks snake through the surface like betrayal. Concrete cracks aren’t just ugly; they’re profit killers. For contractors and DIYers, mastering crack repair means protecting your epoxy investments and reputation.

At EpoxyETC, we’ve supplied thousands with the products and training to conquer this silent saboteur. Let’s turn cracked concrete from a nightmare to a non-issue.

Why Do Cracks In Concrete Occur?

Concrete cracking is most often a result of issues occurring during installation. Generally, it's because it dries too fast. It also obviously could result from normal wear and tear over a concrete's lifetime.

Regardless of the cause, it's essential to resolve the issue as soon as possible. We'll provide a few safety reasons why any cracks are detrimental to you and your floors. It's not just a safety threat, either. Concrete cracks left exposed will take in water. And that water will often freeze, expand, or seep in further, causing even bigger problems for your floor over time.

Why Crack Repair is Non-Negotiable: Safety and Longevity

Every contractor has heard nonstop about surface preparation. You're probably aware of how important it is, not just for aesthetic reasons, but also to guarantee the integrity of your future floor. Whether it's pride or profit, crack repair is a crucial skill to acquire for flooring contract work.

-

Epoxy Failures: Cracks can appear through coatings and even threaten the adhesion of the floor. You may sometimes encounter delamination, or worse.

- As mentioned before, a foundational concrete crack could threaten more than just your epoxy. Water & freezing damage over time will expand cracks in your foundation.

-

Safety Hazards: Trip hazards and structural weakening (OSHA reports that 15% of worksite fatalities stem from trips, slips, and falls).

- These cracks & other physical issues won't just be unsafe, they'll be unsightly!

EpoxyETC’s Crack Repair Arsenal: Precision Products

A not-so-insignificant part of the concrete repair process is the right materials. Resins, concrete repair fillers, application tools, and more. And EpoxyETC sells it all!

1. EpoxyETC ThixoFix Concrete Repair Joint Filler

EpoxyETC's revolutionary ThixoFix solution is one of our strongest and most versatile. For the professional contractors who need an industrial-grade solution with incredible resistance and strength, consider ThixoFix. This polyurethane pulp solution is made to solve issues in garage concrete foundations, or industrial warehouse disasters.

2. Metzger/McGuire MM-80 Epoxy Crack & Joint Filler

Our resource partner's MM-80 Epoxy Crack & Joint Filler is another fit-for-industrial-usage joint filler that'll slot in perfectly for the professional's kit. The MM-80 solution is 100% solids and more tuned for industrial usage, so this may be overkill for the weekend garage contractor.

3. EpoxyETC Quick Dry Crack Filler

This epoxy paste solution is perfect for contractors who prioritize residential and commercial contracts. While it works perfectly as a generalized concrete repair product, it's especially powerful for preparing a concrete foundation for epoxy resin system installation.

4. Application Essentials

-

Grinders: For most narrow cracks, you'll only need an angle grinder capable of minor material removal and grinding to complete the repairs. For a larger industrial job, you may need a more substantial machine.

-

Clean-Up Tools: Masonry tools, hammers, vacuums, washing tools and more. Whether it's old repair material that needs to be removed or removing concrete from your repair area, you'll need to keep your space clean and repair-ready.

-

Manual Cartridge Gun for Concrete Repair: Force fillers deep into substrates. If you suspect your crack is deep into the foundation, you'll need to be able to address it at its root. A cartridge gun or similar tool will help.

The 5-Step EpoxyETC Crack Repair Protocol

Now that you have what you need, it's time to take action. This guide assumes that you have a bare concrete foundation with visible cracking. If your crack appears below an epoxy resin system, contact our technicians for a more accurate game plan. Similarly, if your crack is substantial or requires more than a simple one-day repair, please call our technicians.

Without further ado, here's how you repair cracks in concrete!

Step 1: Diagnose the Culprit

It's important to know whether the crack in your concrete is dormant or active. A good way to test, if you have the time, is to use tape across the crack and let it sit for 48+ hours. A quick-cure concrete repair solution will be your best bet in either scenario.

Assess the size of the problem. You'll need to know how much solution you'll need, as well as if the crack may signify a deeper, more structural issue. If you suspect a foundational issue with your concrete (>1+ inch cracks), call our technicians for more personalized assistance.

Finally, make sure your concrete itself is level! If you're repairing a foundation that is at its core uneven, you'll just be returning to repair it inevitably. Address the deeper causes before you repair the surface-level issues.

Step 2: Prep Like a Surgeon

Crack repair preparation is not too dissimilar from preparing a floor for epoxy installation. You'll need to clean deeply, and ensure the best possible base for adhesion. That means cleaning the crack itself, perhaps widening it so that your concrete repair solution can adequately fill the space.

Vacuum any debris, clean your area, and grind away any obstructive imperfections. If your concrete repair solution is self-leveling, it'll help you reduce the amount of preparation you may need to do. Be aware of where your solution may run off to if you're working on odd-angled spaces such as staircases, or ramps.

Step 3: Fill with Precision

Use your appropriate concrete repair solution to fill the identified problem areas. If they're deeply rooted, use an injection tool to fill the crack entirely. When using a paste-like concrete repair solution, make sure you're filling the space properly.

Focus on your mixing process! An improperly mixed concrete repair solution could not only fail to repair your foundation, but it could also backfire entirely.

Step 4: Cure for Maximum Strength

The hard part is done, now you just need patience. The longer you can allow your concrete repair solution to cure, the stronger it will be in the end. That may mean closing off your clients' driveway for a weekend or more. Ultimately, though, you need to be aware of your specific repair solution's curing time. If you're buying with EpoxyETC, call our technicians for product-specific advice.

Step 5: Finish for Flawless Epoxy

Now you get to make your repair job look flawless! If you're leaving it as bare concrete, finish it off with a simple polish job with an appropriate grit and polishing machine. Don't forget to use a vacuum as concrete dust can be harmful.

We highly recommend finishing off concrete with a polished concrete system at the very least. Use an appropriate epoxy resin protective solution to create a beautiful floor that'll provide immense protection for years to come. If you're working on a garage, convince your client to install a flake, or quartz, epoxy resin system!

3 Crack Repair Blunders That Destroy Epoxy Floors

-

The "Band-Aid" Blunder

- Contractors who overfill a crack, or neglect to adequately prepare their space by widening the crack to an appropriate level. This could lead to problems ranging from as small as an ugly finish, to a failed repair.

-

Rigid Filler in Moving Joints

-

This is why it's important to know whether your crack is active or dormant. A strong-adhesive slow-cure solution is perfect for dormant cracks, but for more-active problems, you'll need a fast-cure solution.

-

-

Ignoring Sub-Slab Voids

- As we have mentioned, a crack can sometimes be a signifier of a deeper, more foundational issue. There are several ways to test for voids in your concrete or moisture issues, so reach out to our specialists for personalized advice on your concrete.

Conclusion

Concrete crack repair doesn't have to be a major obstacle on your journey to perfect epoxy flooring. With a bit of know-how and the necessary tools, you'll be ready to tackle any concrete foundation flaws! Get equipped with our guide and our resources and go install the best epoxy floors for your clients.

Concrete concerns? Reach out to our specialists today at (954) 287-3797! All we want is your success, so buy from our EpoxyETC online store for affordable rates on the best products on the market.